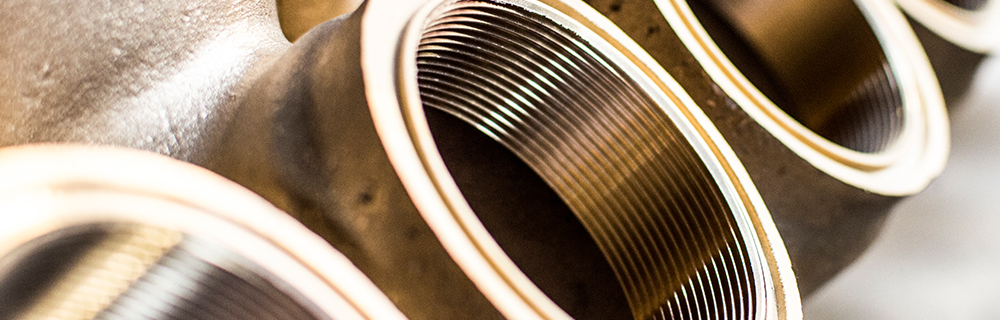

The materials we work with:

Bronze LG2 (CC491K)

Offering excellent machinability, excellent wear resistance to normal lubrication, high resistance to seizure and good corrosion resistance.

Bronze LG4 (CC492K)

offers improved mechanical properties and better resistance to impingement and cavitation attack in contact with fast moving fluids.

Phosphor Bronze (PB2)

Offers good strength and machinability, as well as having good shock and corrosion resistance.

G3

Offers tensile strength, elongation, compressive strength and is impact resistant. It is commonly used in atmospheric corrosive conditions. The metal types used in our manufacturing process are most commonly used for all types of general and constructional castings, particularly in the form of, pressure tight requirements, valve and pump bodies, pump impellers, fittings for gasoline and oil lines, bushings, general engineering applications etc.

RoHS Compliance & Custom Grades

We are also able to offer low lead alternatives where mechanical properties are not critical – please enquire with our technical department if you would like more information or would like to discuss other custom material grades.

Aluminium Bronze AB2 (CC333G)

Offers excellent cavitation, corrosion and erosion resistance in seawater as well as other chloride containing environments, with high wear and abrasion resistance. The alloy is a non-sparking material with excellent performance in cryogenic service.

Downloads: